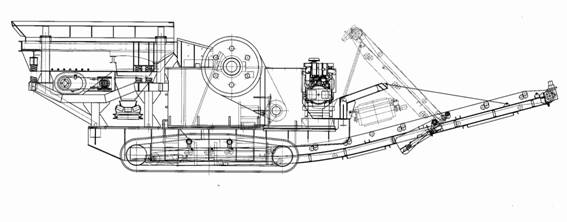

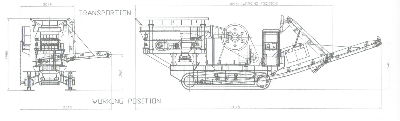

TRACK JAW 600X

900 CRUSHING PLANT

CRUSHER

SINGLE TOGGLE JAW CRUSHER HAVING STEEL FABRICATED STRUCTURE

WITH

MAIN BEARINGS OF AMPLE CAPACITY

CAPABLE OF CRUSHING MATERIALS HAVING COMPRESSIVE STRENGTH UP TO 320Mpa

EASILY ADJUSTABLE OPENING 65 –160mm.

A HYDRAULIC RAM IS PROVIDED FOR QUICK AND EASY SETTING OF THE OPENING

REPLACEABLE JAW AND CHEEK PLATES. ALSO REPLACEABLE SAFETY TOGGLE PLATE

HYDRAULIC DRIVE

HYDRAULIC DRIVE

CRUSHER, FEEDER, CONVEYORS

AND DRIVE ARE DRIVEN BY STURDY HYDRAULIC MOTORS FROM PUMPS DRIVEN BY POWERFUL DEUTZ ENGINE.

HYDRAULIC

REVERSE MOTION [IN CASE OF MATERIAL JAMMING IN THE CRUSHER]

FROM A SINGLE LEVER FROM THE CONTROL PANEL.

AS THE ROTATIONAL SPEED CAN BE ADJUSTED TO SUIT THE TYPE OF MATERIAL, OPTIMUM CRUSHING EFFICIENCY IS ACHIEVED.

THE

HYDRAULIC CIRCUIT IS A CLOSE

THE HYDRAULIC DRIVE HAS PROVISIONS FOR EXTRA HYDRAULIC POWER TO DRIVE ANY ADDITIONAL EQUIPMENT IN CONJUNCTION WITH THIS TRACK CRUSHER.

THE GRIZZLEY FEEDER, CONVEYOR FOR GRIZZLEY FEEDER AND

THE CRUSHER MOTOR AND PUMP ARE COOLED

BY HYDRAULIC OIL WHICH IS COOLED BY A FORCED FAN COOLER BEFORE DISCHARGING TO

TANK.

ALL THESE FEATURES PERMIT EFFICIENT RUNNING OF THE PLANT.

HOPPER

HOPER OF AMPLE CAPACITY WHICH IS FIXED AND CAN BE ACCESSED FROM THREE SIDES PERMITS ---

HOPER OF AMPLE CAPACITY WHICH IS FIXED AND CAN BE ACCESSED FROM THREE SIDES PERMITS ---

USE OF LOADING USING LARGE CAPACITY BUCKETS

GREATER FREEDOM IN POSITIONING OF THIS CRUSHING PLANT ON SITE

FACILITATES USING IT IN COMBINATION WITH OTHER UNITS LIKE SCREENER / SECONDARY

CRUSHING PLANTS LIKE CONE CRUSHER OR HAMMER MILL

VIBRATING

GRIZZLEY FEEDER

1—FEEDS THE MATERIAL GRADUALLY TO THE

CRUSHER AND ITS SPEED CAN BE REGULATED TO PREVENT OVERLOADING OF  THE CRUSHER.

THE CRUSHER.

2—IT SEPARATES MUCK AND UNWANTED MATERIAL RESULTING IN FULL UTILIZATION OF CRUSHING CAPACITY AND INCREASED OVERALL OUTPUT.

A 450MM WIDE CONVEYOR IS PROVIDED TO DUMP MUCK AND MATERIAL BELOW CRUSHING SIZE IN A SEPARATE PILE. THE BELT SPEED OF THIS CONVEYOR CAN BE ADJUSTED TO SUIT THE AMOUNT OF MATERIAL IT IS REQUIRED TO HANDLE TO MINIMISE ENERGY REQUIREMENTS.

10M LONG LARGE CAPACITY VARIABLE SPEED CONVEYOR FITTED

WITH IMPACT & GUIDE ROLLERS, IS OVER 2500mm HIGH [measured from centre of

roller] ABOVE GROUND, PERMITTING BIG PILES

WHICH HELP IN CASES OF SPACE CONSTRAINTS.

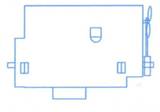

THE CONTROL PANEL

THE CONTROL PANEL

THE ENTIRE MACHINE CAN BE CONTROLLED FROM THE “EASY TO UNDERSTAND” CONTROL PANEL.

· THE DIESEL MOTOR CONTROLS WITH INDICATING LIGHTS

· PRESSURE GAUGES INDICATE INDEPENDENTLY PRESSURE OF EACH PUMP.

·

ON / OFF ROTARY SWITCHES TO CUT IN / OUT CONVEYORS AND  FEEDER, WITH INDICATING LAMPS.

FEEDER, WITH INDICATING LAMPS.

· LEVER OPERATED ARRANGEMENT FOR RAMS FOR FOLDING CONVEYORS AND DRIVING OPTIONAL EQUIPMENT LIKE MAGNETIC SEPERATOR CONVEYOR.

“SAFETY FIRST”

EMERGENCY SELF LOCKING BUTTONS RIGHT IN THE CENTRE OF CONTROL PANEL AND ON BOTH SIDES OF THE CRUSHER OPERATABLE FROM GROUND.

SAFETY GUARDS ON ALL ROTATING AND MOVING PARTS

SAFETY GUARDS ON ALL ROTATING AND MOVING PARTS

· PLATFORM HEIGHT TO PROVIDE NECESSARY VISIBILITY, WITH RAMPS [NO STEPS].

· WALKWAY WITH HANDRAILS

· SEPARATE PANEL FOR DRIVING ONLY—HAVING ONLY TWO LEVERS-PROTECTED BY LOCKABLE COVER TO PREVENT ACCIDENTAL OPERATION.

MAINTENANCE FREE

NOTE: ALL COMPONENTS USED IN THIS MACHINE ARE FROM THE LEADING MANUFACTURERS

AND OF HIGH QUALITY.

SIMPLE STRAIGHT FORWARD DESIGN FREE OF COMPLICATED ELECTRONICS AND HIGH QUALITY COMPONENTS ENSURE TROUBLE FREE SERVICE.

MOBILITY

THE PLANT CAN TRAVEL OVER ROUGH TERRAIN AS IN QUARRY OR AT DEMOLITION SITE.

THE DRIVE MOTORS OF EACH SIDE IS FED BY TWO SEPARATE PUMPS.

THE CONVEYORS CAN BE FOLDED, WITH SUFFICIENT CLEARANCE BETWEEN GROUND AND MAIN CONVEYOR, THUS PROVIDING FOR EASE OF TRANSPORT.

MAGNETIC SEPARATOR---

A STANDARD FEATURE

A MAGNETIC SEPARATOR IS FITTED OVER THE MAIN CONVEYOR TO SEPARATE STEEL FROM THE CRUSHED DEBRIS, SO THAT CRUSHED CONCRETE CAN BE RECYCLED FOR CONSTRUCTIONAL USE.

SPECIFICATIONS—

MAGNETIC FIELD INTENSITY –63 Mt SUITABLE FOR 800mm WIDE BELT

RECOMMENDED SUSPENSION HEIGHT 200mm WEIGHT 1400Kg DIMENSION 2460X1253X 737

SPECIFICATIONS

SPECIFICATIONS

CRUSHER TASMAN 600X900

|

SIZE OF

FEED OPENING |

600 X 900 mm |

|

MAXIMUM

FEED SIZE |

500mm |

|

ADJUSTABLE

|

65 –160 |

|

CRUSHING CAPACITY |

30-75CUBIC

METERS[ UP TO 170T OR MORE DEPENDING ON MATERIAL] |

CONVEYORS # FOLDING TYPE FOR

TRANSPORT

|

MAIN

CONVEYOR

# |

10M LONG X 800 mm WIDE |

BY

PASS CONVEYOR #

|

3.8M LONG X 450 mm WIDE |

MAGNETIC

SEPARATOR

|

2.5M LONG X 785 mm WIDE |

GRIZZLEY

FEEDER

HORIZONTAL

TYPE - VARIABLE SPEED

MAXIMUM

FEED SIZE

|

500mm |

SIZE OF

HOPPER

|

3800 X960 |

CAPACITY

|

UP TO 170T

[DEPENDING ON MATERIAL]

|

ECCENTRIC

SHAFT SPEED

|

500- 714 RPM |

ENTIRE PLANT IS HYDRAULICALLY DRIVEN

ENGINE DEUTZ BF6m1013EC

ENGINE DEUTZ BF6m1013EC

WATER COOLED Turbo Intercooled

6

CYLINDER-108 BORE X 130 STROKE

COMPRESSION RATIO 17.6

174 Kw @ 2300rpm

HYDRAULIC

TANK

|

700L

|

DIESEL TANK

|

380 L |

TANKS

TANKS

DIMENSIONS

WEIGHT 35T APROX

[WORK] 13620Lx5080Wx3980H

[TRANSPORT] 10960Lx2970Wx3980H

Due to CONTINUOUS

PROCESS OF IMPROVEMENTS & DEVELOPMENT,

MATERIALS

MANAGEMENT & SUPPLIES LTD. RESERVE THE RIGHT TO CHANGE SPECIFICATIONS

WITHOUT PRIOR NOTICE!